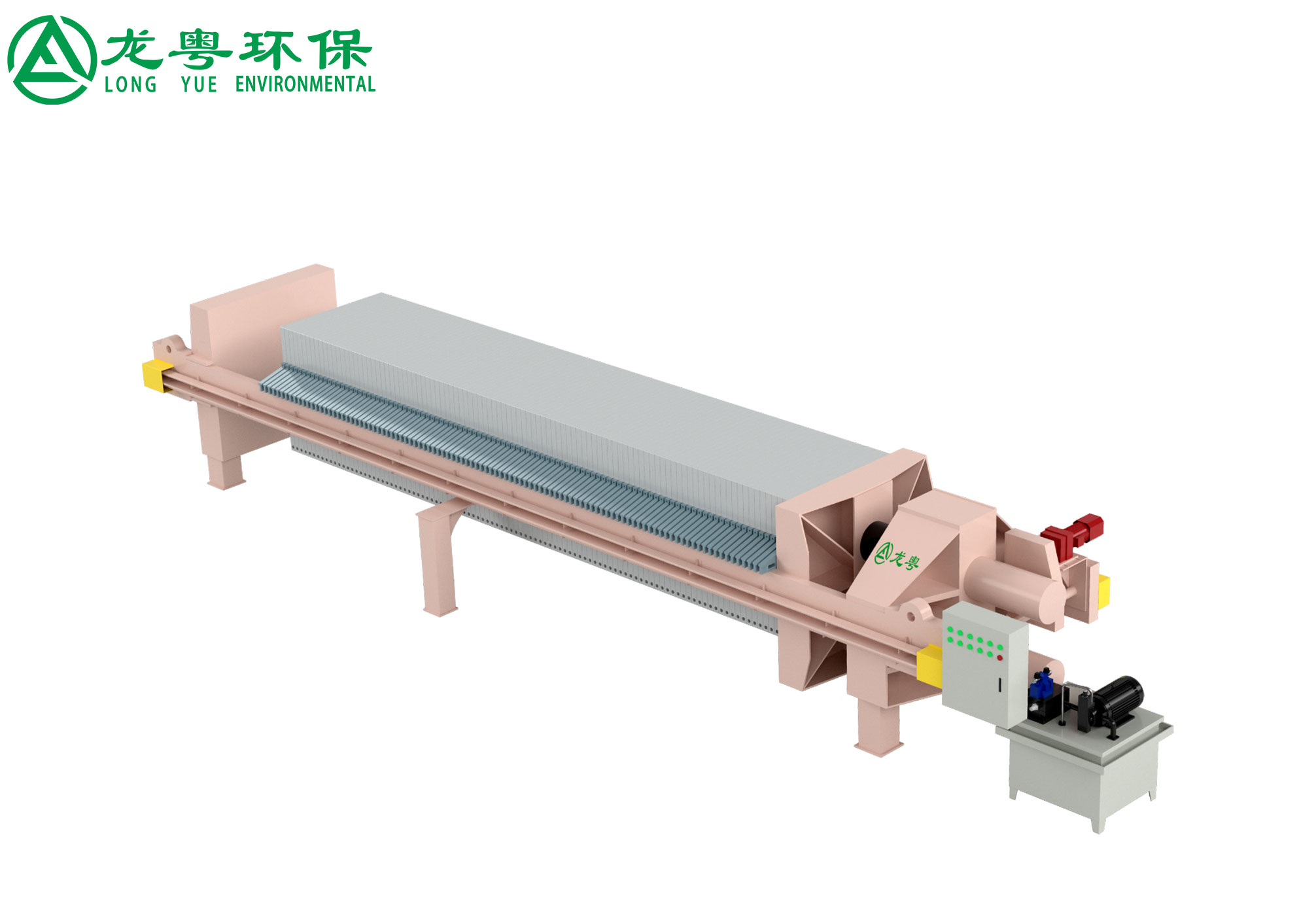

A chamber filter press consists of an array of filter plates (with recessed sides, so that every two plates form a chamber). The filter plates have pitting and projections on their surfaces to support the filter cloth.

+86 159 8632 910 (whatsapp)

+86 159 8632 910 (whatsapp) A chamber filter press consists of arranged filter plates forming a filter chamber (with recessed sides, so that two filter plates form a chamber). The filter plates have pits and raised projections on their surfaces to support the filter cloth. Through holes are located in the center and corners of the filter plates, forming a complete channel when assembled, allowing the inlet of suspensions, wash water, and the outlet of filtrate. Handles on either side of the filter plates support the crossbar, which holds the filter plates in place. The filter cloth between the plates acts as a seal.

Under the pressure of the feed, the liquid to be filtered is fed into each filter chamber. It passes through the filter medium (selected according to the industry), separating the solids and liquids to form a filter cake, until the chamber is filled. The filtrate passes through the filter cloth and flows along the grooves of the filter plates to the outlet channel below for centralized discharge. After filtration, the filter can be cleaned, rinsed with water, and the residue removed. After washing, compressed air is sometimes introduced to remove any remaining filtrate. After filtration is complete, open the filter press, remove the filter cake (the filter cake is stored between two adjacent filter plates), clean the filter cloth, and re-press the filter plates to begin the next cycle.